In nature, butterfly wings strike a delicate balance between lightness and toughness owing to their unique hierarchical structure. The mechanical gradient distribution within their wing scales, refined over millions of years of evolution, not only effectively disperses flight-induced stress but also provides a biological blueprint for next-generation smart materials.

By decoding the mechanical gradient secrets of butterfly wing scales, a joint research team led by Prof. Lianqing Liu from Shenyang Institute of Automation, Chinese Academy of Sciences and Prof. Wen Jung Li from City University of Hong Kong developed a single-step femtosecond laser 4D printing technology that enables rapid and precise deformation in micron-scale smart hydrogels, paving new avenues for flexible electronics and minimally invasive medicine.

This work is published online in ACS Materials Letterson Feb.17.

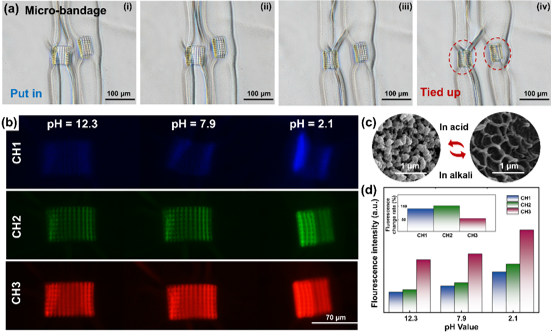

Two potential applications based on 4D printed customized hydrogels design of microstructures (Image by the research group)

Inspired by the wing structure of Papilio maackii, the team discovered that honeycomb-like pores and reinforced textures on the wing surface synergistically dissipate mechanical stress during flight. Mimicking this natural design, they employed femtosecond laser technology to sculpt pH-responsive hydrogel structures. By adjusting laser scanning modes, a gradient distribution of alternating soft and rigid regions was programmed into the material, akin to embedding a deformation code.

Experiments and Finite Element Analysis revealed that exposure to acidic solutions triggers the hydrogel to fold automatically within one second, shrinking to 25% of its original volume.

The breakthrough lies in single-step fabrication. Traditional methods require layering multiple materials to achieve deformability, whereas this innovation directly encodes mechanical heterogeneity during printing.

The hydrogel exhibits dual functionality: sensing environmental changes and actuating structural responses. In medical demonstrations, smart dressings automatically wrap biomembranes with micron-level precision as pH shifts. For sensing applications, the material’s fluorescence intensity fluctuates by up to 110% during acid-base transitions.

This streamlined 4D printing approach marks a leap forward in micro/nanoscale manufacturing, unlocking novel applications for responsive hydrogel systems—from adaptive medical devices to eco-friendly flexible electronics.