Metallurgical industry has always been a major energy consumer in China, and is the key industry to promote energy conservation and consumption reduction. Because hot blast stove and heating furnace are key factors in lowering consumption, experts focus on combustion control and optimization to find out solutions.

To realize the optimal control of heating furnace, it is necessary to overcome the problems of various raw material sources, variable production conditions and frequent fluctuation of working conditions in the production process, and accurately predict the temperature of each heating zone of the furnace. It is also necessary to meet the real-time requirements of the working conditions, and puts forward higher requirements for the calculation efficiency and calculation time of the prediction algorithm.

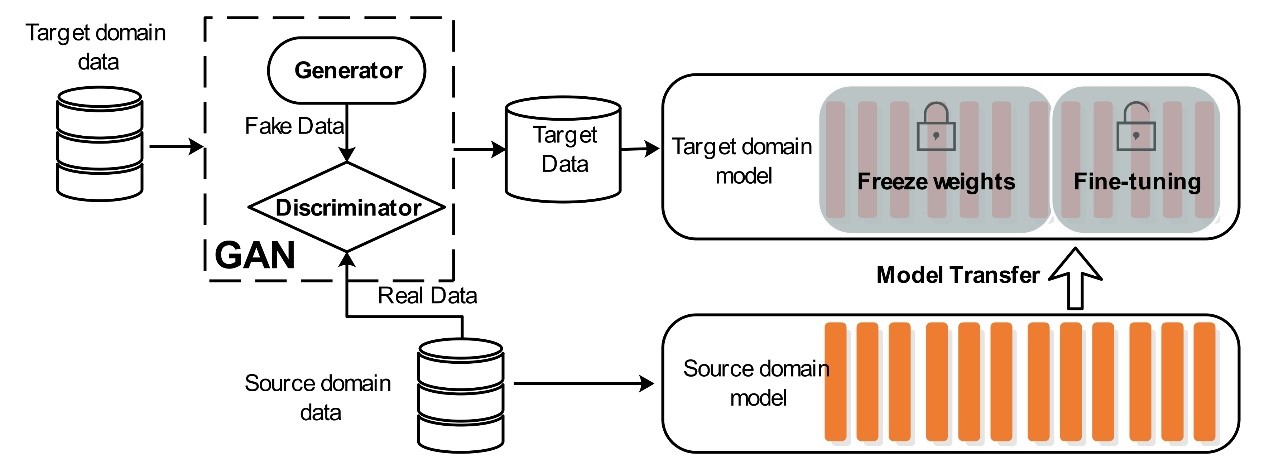

To address these challenges, a research team at Shenyang Institute of automation, Chinese Academy of Sciences, proposed a temperature prediction algorithm for heating furnace based on transfer learning.

The prediction accuracy was improved by the generative adversarial network, and finally a real-time furnace temperature prediction model was formed. The case study shows that the furnace temperature prediction framework based on transfer learning proposed by the team can greatly improve the prediction accuracy on the basis of rapid modeling of each heating zone. The relevant academic achievements have been published in sensors, which also provides a new method for the application of artificial intelligence technology in the optimization control of heating furnace energy consumption in metallurgical industry.

In recent years, the Digital Factory Laboratory has conducted methodological research in the field of intelligent manufacturing relying on the Zhongke Cloudwing Connected Manufacturing Platform system. A series of high-level research results has been achieved which providing theoretical basis and technical support for the deep integration of artificial intelligence and big data technology with manufacturing process.