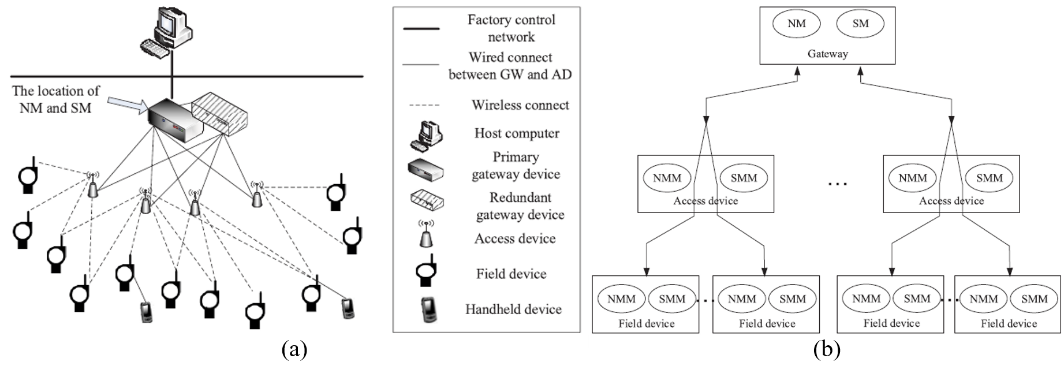

Redundant star topology of WIA-FA (Photo by LIANG Wei)

Imagine a large group of automated guided vehicles (AGVs) carrying large components in a manufacturing workshop instead of manual laborers. This will soon become a reality, thanks to a major breakthrough in industrial wireless control networks.

Recently, a group of Chinese researchers from Shenyang Institute of Automation, Chinese Academy of Sciences proposed Wireless networks for Industrial Automation-Factory Automation (WIA-FA), which is the first and only approved international standard of industrial wireless control networks for factory automation.

WIA-FA, approved by the International Electrotechnical Commission (IEC) as a standard in 2017, has been successfully applied in monitoring and controlling industrial robots in digital workshops, wirelessly connecting AGVs in logistic systems and coordinating multiple cooperative AGVs, according to a recent study published in Proceedings of the IEEE. The data period of nodes can be less than 10ms for networks with 100 nodes, and communication reliability can reach above 99.99%.

Wireless networks in intelligent manufacturing factories must meet strict requirements in terms of latency and reliability. Typical industrial environments include many sources of strong noise and interference, such as broad operating temperatures, ignition systems, vibrations, etc. Besides, manufacturing factories tend to be filled with obstacles and metallic materials, which severely disturb wireless transmissions. Therefore, it is quite challenging to guarantee the transmission reliability when mobile robots, such as AGVs move from place to place on a work site.

WIA-FA defines a group of physical devices, each capable of fulfilling one or more functions. The physical device of WIA-FA includes host computer, gateway device, access device, field device, and handheld device. A redundant star topology is defined for WIA-FA. The redundant star topology is formed by the gateway device with multiple access devices, where each access device further forms a star topology with multiple field devices. The access devices of WIA-FA do not directly communicate with each other but communicate with the gateway by wired connection. Therefore, all access devices are synchronized with the gateway. The access devices are with the same address and transparent for field devices. A field device may connect with multiple access devices wirelessly.

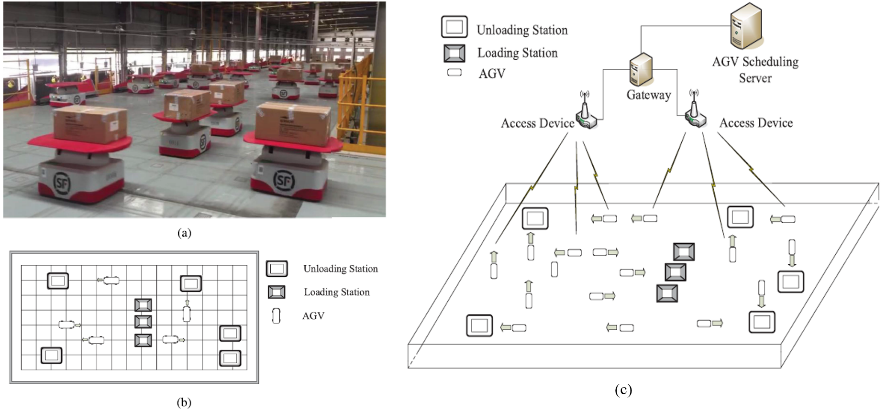

“The AGVs have become the killer application of WIA-FA networks, especially in warehouse and logistics” said LIANG Wei, the leading researcher of the study. The fast mobility of AGVs calls for advanced wireless technologies for the networking of an AGV system. WIA-FA has been running stably and successfully on AGV scheduling system in Yunnan KSEC Intelligent Equipment Company, Ltd., which is the second largest AGV Company in China since January 2017. The average traffic data flow of each AGV could reach up to 100 Kbyte/s, with transmission reliability above 99.99%.

WIA-FA for AGV logistics sorting. (a) Field environment. (b) System layout. (c) WIA-FA network architecture (Photo by LIANG Wei)

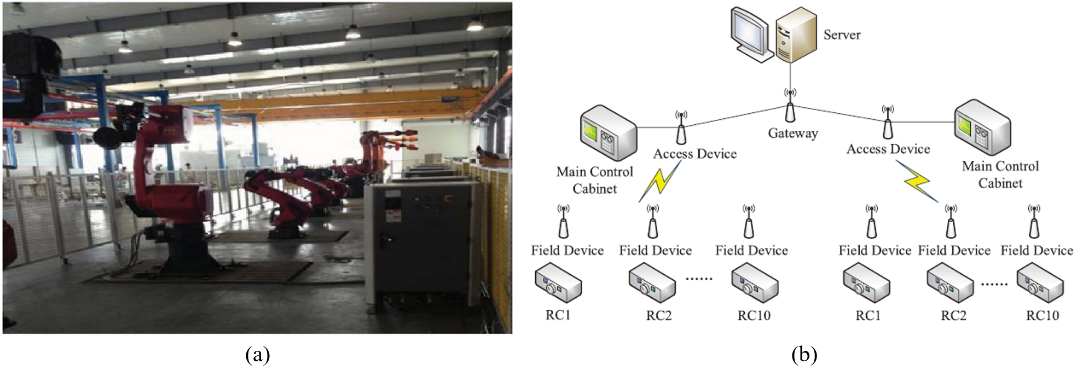

Another representative application of WIA-FA is the remote monitoring of industrial robots on the production line in the digital workshop of the SIASUN Company, which is the largest industrial robot company in China. WIA-FA is configured to wirelessly transmit the operating parameters such as working voltage, current, motor temperature, rotation speed to the main control cabinet. The deployed WIA-FA network has been stably running for more than two years.

WIA-FA for industrial robot remote monitoring. (a) Field environment. (b) WIA-FA network architecture (Photo by LIANG Wei)

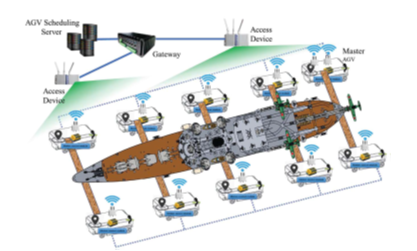

“WIA-FA also has great application potential in the cooperation of multiple industrial robots, for example when multiple AGVs are required to carry large and complex components.” said LIANG. Under such scenario, the master AGV is equipped with two WIA-FA field devices: one for the communication with the AGV scheduling server and the other for the cooperative communication with other slave AGVs. After being grouped, all the motion information of the slave AGVs in one group including the location, speed, and acceleration are periodically reported by their master AGV to the AGV server.

The communication system of multiple cooperative AGVs (Photo by LIANG Wei)

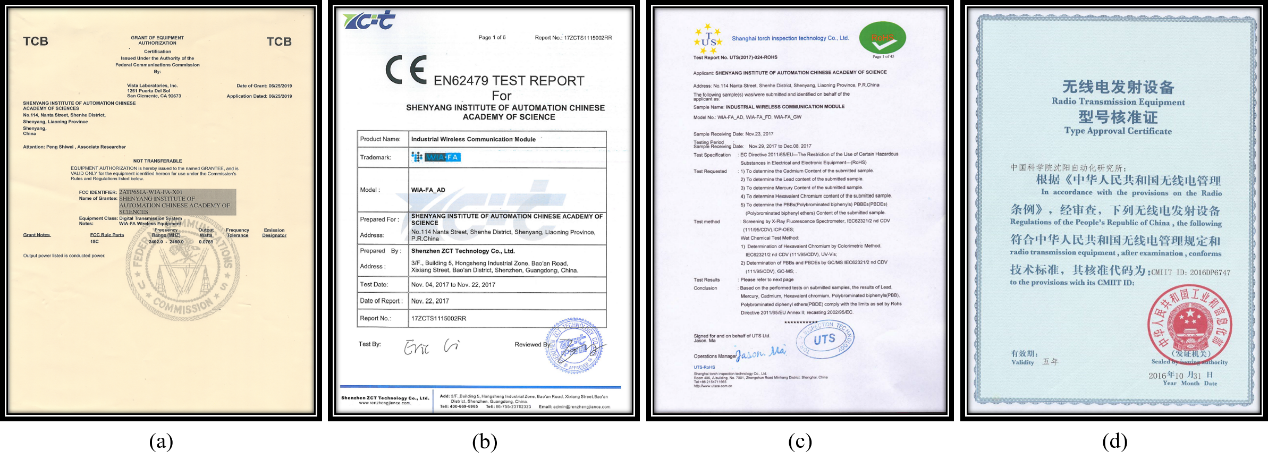

Equipment developed based on WIA-FA have received the Federal Communications Commission (FCC) certification of the United States in 2019, after being granted Certification of Compliance (CE), Restriction of Hazardous Substances (ROHS) by the European Union in 2017 and Radio Transmission Equipment Type Approval Certificate (RTETAC) by State Radio Regulatory Committee (SRRC) of China in 2016.

Certificates for WIA-FA. (a) FCC. (b) CE. (c) ROHS. (d) RTETAC (Photo by LIANG Wei)

“WIA-FA solution has made breakthroughs in tackling bottleneck problems as high concurrency, anti-interference and hard real-time, etc. WIA-FA solution takes the lead and will certainly play an important role in the technology upgrading of factory automation.” said Ruby Belliardi, the secretary of IEC/TC65 (technical committee under the IEC to prepare international standards for systems and elements used for industrial process measurement, control and automation) .

Contact:

LIANG Wei

Photo: 86-24-23970198

Email: weiliang@sia.cn