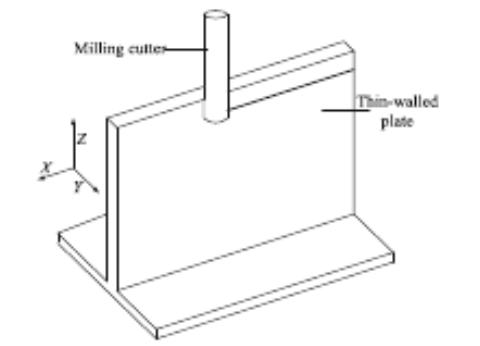

Thin-walled plate in end miling. (Image from the original paper)

Stability lobe diagram can be used for selecting proper milling parameters to perform chatter-free operations and improve productivity during milling of thin-walled plates. This paper studies the machining stability in milling of thin-walled plates and develops a three-dimensional stability lobe diagram of the spindle speed, tool position, and axial depth of cut. The workpiece-holder system is modeled as a 2-degree-of-freedom system considering that the tool system is much more rigid than the thin-walled plate, and dynamic equations of motion described for the workpiece-holder system are solved numerically in time domain to compute the dynamic displacements of the thin-walled plate. Statistical variances of the dynamic displacements are then employed as a chatter detection criterion to acquire the stability lobe diagram. The experimentally obtained stability limits correspond well with the predicted stability limits. In addition, influence of feed rate on stability limits is also investigated. By performing frequency analysis of the measured cutting forces to judge if chatter occurs, it is found that feed per tooth has little influence on the stability limits. However, feed per tooth impacts the machined surface quality. The results show that the surface quality drops by increasing feed per tooth.

This study was published on International Journal of Advanced Manufacturing Technology,2016:1-10.titled Three-dimensional stability prediction and chatter analysis in milling of thin-walled plate.