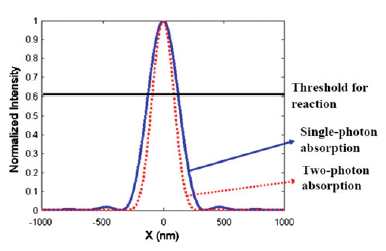

Spatial distributions of laser energy absorbed by transparent materials by single (blue solid line) and two-photon (red dashed line) absorption. The solid horizontal line indicates the reaction threshold (Image provided by LIAO Yang et.al)

Until recently, femtosecond laser fabrication of hollow 3D microfluidic structures in glass has been achieved mainly through two approaches: femtosecond-laser-assisted chemical etching and liquid-assisted femtosecond laser 3D drilling. Although these techniques have indeed shown extreme flexibility for 3D microfluidic application, two major issues still exist. The first issue is the limited size of the microfluidic structures obtained with these techniques, which is usually in the range of a few millimeters to one centimeter. The second one is the limited fabrication resolution mainly caused by optical diffraction limit. Currently, the thinnest nanochannels were obtained by liquidassisted femtosecond laser 3D drilling, resulting in channel diameters ranging from 500 to 700 nm.

In general, the mechanism behind thethe formation of the single nanochannels can be understood as a combination of the threshold effect and the formation of periodic nanograting during the process of laser writing in a porous glass immersed in water. Thus, the process is intrinsically sensitive to the laser peak intensity which has to be confined in a limited window, as the researchers have explained previously. In this study, we show that the effective range of laser intensity for fabrication of nanochannel can be expanded by optimizing the laser pulse duration. The broadened processing window can make the fabrication more stable against the fluctuation of laser peak intensity and the fabricated nanofluidic structures more uniform. In addition, the dependence of the effective range of laser intensity for fabrication of nanochannel, which relies on the formation of a single nanocrack in a nanograting, will shed more light on the mechanism behind the nanograting formation in transparent materials with femtosecond laser irradiation.

Recently, researchers from Shenyang Institute of Automation (SIA), the Chinese Academy of Sciences (CAS), together with researchers from State Key Laboratory of High Field Laser Physics, Shanghai Institute of Optics and Fine Mechanics, CAS, and from Laser Technology Laboratory, RIKEN, Advanced Science Institute, Japan have tackled the first issue by a new strategy, which adopts femtosecond laser direct writing in porous glass immersed in water followed by postannealing, enabling fabrication of microfluidic channels with nearly unlimited lengths and arbitrary 3D geometries. Slightly later, the researchers further exploit the potential of this strategy for resolving the second issue as mentioned above. The researchers have shown that nanochannels with transverse widths down to \50 nm can be directly fabricated inside consolidated glass. The nanochannels can be easily integrated into 3D microfluidic systems which are simultaneously formed in a glass substrate for performing single-molecule DNA analysis

This work was published on Applied Phycisc A (2014) 114, pp 223--230, and was financially supported by National Basic Research Program of China (2014CB921300, 2011CB808100) and National Natural Science Foundation of China (60921004, 61275205, 61108015, and 11104294). The authors also thank the support from the State Key Laboratory of Robotics.

Contact:

CHENG Ya

Email: Ya.cheng@siom.ac.cn