Scanning Ion Conductance Microscopy (SICM) is one kind of Scanning Probe Microscopies (SPMs), and it is widely used in imaging soft samples for many distinctive advantages, such as: high resolution imaging, simple preparation of probe and no damage to samples surface. However, the scanning speed of SICM is much slower than that of other SPMs, especially for large scale and high resolution imaging.

In order to solve this problem, researchers from Shenyang Institute of Automation, the Chinese Academy of Sciences (CAS) brought the compressive sensing (CS) theory into the SICM quick imaging. Compressive sensing breaks through the Shannon sampling theorem, but it still costs much time in image reconstruction.Therefore, the researchers applied block compressive sensing to further reduce the reconstruction time of sparse signals. Besides, block compressive sensing can achieve the function of image real-time display in SICM imaging.

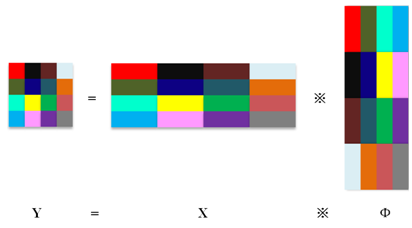

The theory of block compressive sensing is to divide the measurement matrix and the sparse signal into several blocks,and to guarantee effective signal reconstruction,Then, a new matrix operation was proposed for block compressive sensing, called Block Matrix Part Arithmetic (BMPA), as shown in figure 1.

Figure 1. The illustration of BMPA in detail. Any block indicated by a certain color of Y equals to the production between the blocks of the same color in Φ and X, for the corresponding pair of submatrices of the measurement matrix and the original signal, abiding by the BMPA operation.(Image provided by LI Gongxin et al.)

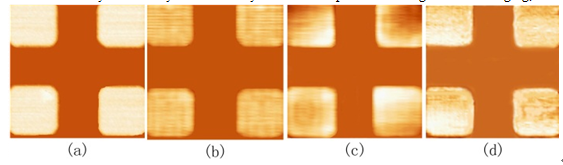

In order to verify the validity and efficiency of block compressive sensing in SICM imaging, researchers conducted several experiments, the results are shown as in figure 2.

Figure2. Comparison among different imaging methods. (a) The image with traditional sampling method by acquiring all signals of the sample surface. (b) The image with traditional compressive sampling method by acquiring half of the original signals. (c) The image with blocks compressive sampling method by dividing the sample into 2×2 blocks and acquiring half of the original signals. (d) The image with blocks compressive sampling method by dividing the sample into 3×3 blocks and acquiring half of the original signals.(Image provided by LI Gongxin et al.)

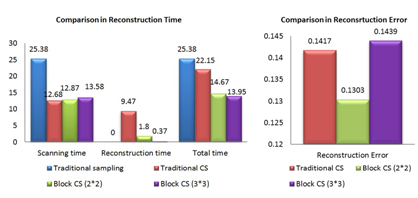

Figure 3. Comparison in reconstruction time and error with different sampling methods. (a) Comparison among reconstruction times with traditional sampling, traditional CS and two block CS of different block-dividing strategies. (b) Comparison among reconstruction errors using different compressive sensing methods in term of the percentage with respect to the original image acquired using traditional sensing approach.(Image provided by LI Gongxin et al.)

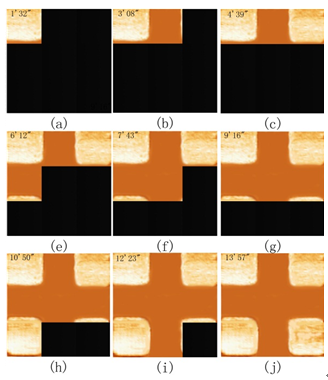

Figure4. Real-time display of SICM imaging. (a)~(j) The image display of SCIM imaging sorted by display time.(Image provided by LI Gongxin et al.)

This work was presented in 2013 International Conference on Manipulation, Manufacturing and Measurement on the Nanoscale (3M-NANO) held in Suzhou, China, and also published on International Journal of Optomechatronics, Volume 8(3): 218-227. It is supported by the National Natural Science Foundation of China (Grant No. 61327014), the National High Technology Research and Development Program of China (Grant No. 2012AA020103) and the CAS/SAFEA International Partnership Program for Creative Research Teams.

CONTACT

Li Gongxin

Shenyang Institute of Automation, the Chinese Academy of Sciences

Email:ligongxin@sia.cn