The station control layer includes monitoring console, store database. The spacing layer is formed by data set gateway. The process layer includes temperature monitoring node.

Due to the complex electromagnetic environment and metal obstructions, node to node communication cannot ensure the stability of wireless network. The researchers select WIA-PA wireless communication protocol which was tested in the industry scene as protocol between data set gateway and temperature monitoring nodes.

The protocol adopts mesh-star network flexibly, and it has ad hoc network function. Every temperature monitoring node could assess the quality of wireless channel automatically and select high quality channel by itself

The hardware electric circuit of temperature monitoring node is formed by microprocessor minimum system, RF circuit, sampling circuit, power circuit, and filter circuited. A power program is also designed, combing the battery power and affixed coil power.

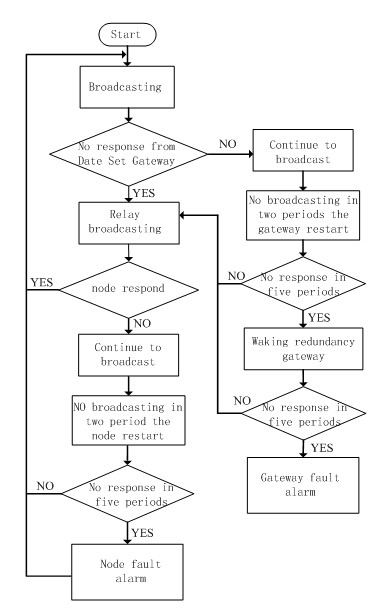

The program of wireless temperature monitoring system is smart. The console sends broadcast to the date set gateway and temperature monitoring nodes. If a data set gateway or a node does not respond, the console continues to send broadcast to the data set gateway. If a data set gateway or a node does not receive broadcasting in two periods, it resets.

If the console continues to broadcast five periods and does not receive the information of a node, it alarms. The working flow chart is shown in figure 2.

Fig2. Inquire flow diagram of system (Image provided by WANG Qiushi, et.al)

This work was presented on the 2013 25th Chinese Control and Decision Conference (CCDC) held in May this year in the city of Guiyang, China. It is supported by National major Project (2010ZX03006-005-01,2011ZX03005-002), National Nature Science Foundation (61100159), National 863 Plan (2011AA040101, 2011AA040103), China Academy of Science Major Project (KGCX2-EW-104).

CONTACT:

Qiushi Wang

Shenyang Institute of Automation, the Chinese Academy of Sciences

Email: wangqiushi@sia.cn