First conceptualized by Stommel, underwater gliders have been developed worldwide. With the features of low cost, long range and long duration, underwater gliders have already been adopted by a number of oceanographic research and littoral survey missions and proven as efficient platforms for oceanic elements sampling. For an underwater glider, developing effective methods to increase its gliding range is a key issue. Several research results on this issue have been reported in the literature, which are typically based on optimal control and motion planning and are required to be implemented on a commanding computer outside of gliders.

Researchers from Shenyang Institute of Automation (SIA), Chinese Academy of Sciences developed alternative computationally efficient methods to increase the gliding range of underwater gliders by optimizing gliding motion parameters and by sensor scheduling. Given a particular design of an underwater glider, the proposed strategies could be implemented in the embedded computing units carried by the glider; hence less computing power is necessary compared to the methods based on optimal control and motion planning. Both of the proposed methods are evaluated on the Sea-Wing underwater glider, which is developed at SIA, as shown in Figure 1. The experimental study on the Sea-Wing underwater glider validates the effectiveness of the proposed methods.

Figure 1. The Sea-Wing underwater glider developed at SIA, which consists of a cylindrical pressure hull to which horizontal wings, vertical fixed rudders, and a trailing antenna are attached. The subsystems inside the pressure hull include the buoyancy-regulating device, the pitch-regulating device, the roll-regulating device, the embedded control subsystem, the communication and navigation subsystem, the emergency release subsystem, and the science sensors. (Image provided by YU Jiancheng, et.al)

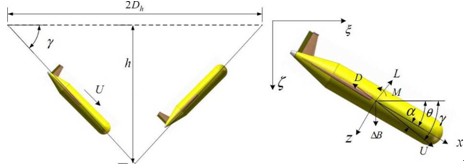

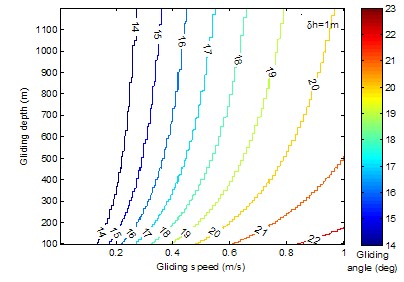

The first strategy is motion parameters optimization. To implement the strategy, an applied mathematical model for the gliding range is first established, which includes the model of the steady-state gliding motion of a glider and some energy consumption models of subsystems onboard a glider. The steady gliding motion model describes the relationship of the glider’s steady gliding motion and its related motion parameters, as shown in Figure 2. The energy consumption models establish the relationships among energy consumption of subsystems and steady gliding motion parameters including the gliding depth, the gliding angle and the gliding speed. Currently, the developed energy consumption models contain a model of the buoyancy-regulating device, a model of the pitch-regulating device, a model of the embedded control system, and a model of sensors. Based on the developed model, a set of optimal motion parameters for the maximum gliding range could be obtained by performing mathematical optimization. Figure 3 shows a result of the numerical optimization of the gliding angle using the proposed method, given the expected gliding depth, the gliding speed and the oceanic element’s sampling resolution.

Figure 2.The motion parameters and their relationships to the steady-state gliding of an underwater glider. The origin of the body-fixed coordinate system is set at the center of buoyancy, where is the gliding angle, is the angle of attack, is the pitch angle, is the gliding speed, and are the lift and the drag, is the hydrodynamic torque, is the gliding depth, and is the horizontal gliding distance achieved in a gliding cycle. (Image provided by YU Jiancheng, et.al)

Figure 3. The optimal gliding angle of the Sea-Wing underwater glider for the maximum gliding range under different gliding speed and gliding depth. The sampling resolution is set as 1 meter. (Image provided by YU Jiancheng, et.al)

Since the science sensors mounted on an underwater glider cost a significant proportion of the total energy consumption, another effective approach to increase the gliding range is by reducing the energy consumption of sensors during operation. Because there is coupling between the variables to be measured and depth, a sensor scheduling strategy that dynamically adjusts the sampling resolution based on real-time sensor measurements is developed. The strategy first defines a sixth-order polynomial to approximate the relationship function of a measured variable with depth, and then adopts the least square method to estimate the coefficients of the polynomial function with previously sampled data and employs the first-order derivative of the polynomial to indicate the variation rate of the variable. The sampling resolution is then adjusted in real-time based on the variation rate, i.e., with larger variation rate, higher sampling resolution should be set; on the contrary, smaller sampling resolution could be applied, thus energy could be saved and the gliding range could be further increased without seriously degrading the quality of collected data.

The proposed motion parameters optimization and sensor scheduling methods are effective for increasing a glider’s gliding range, and they are also applicable to glider design phase to optimize the glider design. In future works, effects of the ocean current will be considered to optimize the gliding range under certain modes of ocean flow.

This work was published on the journal of IEEE JOURNAL OF OCEANIC ENGINEERING, 2013, Digital Object Identifier 10.1109/JOE.2012.2227551. It was partly supported by the Defense Industrial Technology Development Program of China under Grant B1320110060 and by the Knowledge Innovation Program of the Chinese Academy of Sciences under Grant KZCX2-YW-JS205.

CONTACT:

Prof. YU Jiancheng

Shenyang Institute of Automation, Chinese Academy of Sciences

Email: yjc@sia.cn