Electromagnetic coils are widely used components in many applications and systems, including solenoids, motors and transformers. However, coil insulation systems are failure-prone, especially under excessive thermal stresses, leading to unexpected machine shutdown.

As the use of low-voltage (under 1kV) electrical rotating machines are more widely in new applications, especially in more-electric aircraft, the reliability of the low-voltage coil insulation systems in rotating machines has thus become a critical issue and requires technical-conditions-monitoring to avoid unexpected shutdown of machines that incorporate electromagnetic coils.

A jointly research team of Shenyang Institute of Automation, the Chinese Academy of Sciences and University of Maryland has recently looked into the issue and provide a possible solution for better achieving the degradation monitoring of insulation systems used in low-voltage electromagnetic coils under thermal loading conditions.

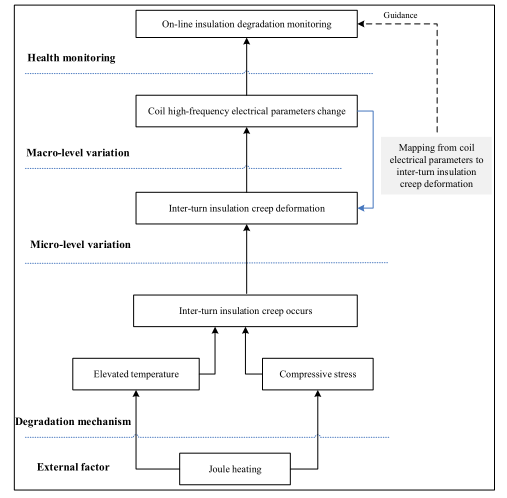

Framework for coil insulation degradation monitoring from a creep point of view developed in the study. (Image by WANG Kai, etc.)

They investigated degradation monitoring of coil insulation systems under thermal loading conditions from a creep point of view, and released their study titled Degradation Monitoring of Insulation Systems Used in Low-Voltage Electromagnetic Coils under Thermal Loading Conditions from a Creep Point of View in Sensors, on July 1st, 2020.

Long-term thermal and compressive stresses placed on the insulation during coil operation create the necessary conditions for the occurrence of inter-turn insulation creep. Therefore, the researchers hypothesized coil creep degradation mechanism during coil incipient degradation phase. They also developed a mapping method from coil electrical parameters to inter-turn insulation creep deformation based on circuit theories and optimization methods.

To prove the developed method, the researchers performed thermally accelerated tests. Polymer creep curves obtained by outer radius measurement results of magnet wires and comparison between mapped and measured creep deformation during the thermally accelerated tests validates the proposed creep degradation mechanism and mapping method.

“This study bridges the gap between the micro-level and macro-level changes during the incipient insulation degradation process, and we established a knowledge base for insulation degradation monitoring by converting the electrical monitoring parameter to coil insulation health status.” said Prof. WANG Kai, the corresponding author of the paper.

This finding helps to reveal the practical physical meaning of coil high-frequency electrical parameters and enhance the prognostic ability of existing high-frequency electrical parameter based insulation monitoring methods, which presents opportunities for predictive maintenance of machines that incorporate electromagnetic coils.

Contact:

WANG Kai

Email: wangkai@sia.cn